|

||

|

Orton Ceramic Foundation / USA |

||

|

||

|

|

|

||

|

Orton Ceramic Foundation / USA |

||

|

||

|

|

|

Automatic Annealing

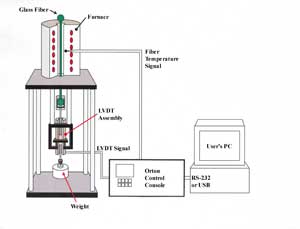

& Strain Point Determination 測定時間只需25分鐘  The system is initially heated to an equilibrium

soak temperature 25°C below the expected annealing point, and waits for

the next test. After the fiber is inserted and the weight applied, the

START button is pushed and the Orton controller heats the furnace at 5ºC

per minute. The temperature and LVDT signals of the elongating fiber are

captured by the controller's on board computer, where the elongation

rate is calculated and monitored. Once the elongation rate exceeds 0.60

millimeters per minute, the Orton controller cools the furnace at 4°C

per minute. While the furnace is cooling, the temperature and LVDT

signals are captured by the controller's on board computer for

storage. Once the elongation rate falls below 0.10 millimeters per

minute, the test is concluded and the annealing point temperature

(elongation rate of 0.14 millimeters / minute) is displayed on the

console display until the system is reset. The furnace automatically

cools to the soak temperature in about 15 minutes, and is ready for the

next test. The on board computer can store data for up to 10 tests. The system is initially heated to an equilibrium

soak temperature 25°C below the expected annealing point, and waits for

the next test. After the fiber is inserted and the weight applied, the

START button is pushed and the Orton controller heats the furnace at 5ºC

per minute. The temperature and LVDT signals of the elongating fiber are

captured by the controller's on board computer, where the elongation

rate is calculated and monitored. Once the elongation rate exceeds 0.60

millimeters per minute, the Orton controller cools the furnace at 4°C

per minute. While the furnace is cooling, the temperature and LVDT

signals are captured by the controller's on board computer for

storage. Once the elongation rate falls below 0.10 millimeters per

minute, the test is concluded and the annealing point temperature

(elongation rate of 0.14 millimeters / minute) is displayed on the

console display until the system is reset. The furnace automatically

cools to the soak temperature in about 15 minutes, and is ready for the

next test. The on board computer can store data for up to 10 tests.If desired, a separate, independent computer system (not included) can be connected to the Orton controller console via a RS232 port for real time monitoring and analysis. During the test the fiber elongation rate, time, and temperature are displayed on the monitor and stored on the hard drive in a text file. At the conclusion of the test, the software automatically and immediately calculates the annealing point temperature (elongation rate of 0.14 millimeters / minute) and the extrapolated strain point temperature (elongation rate 0.0316 times the annealing point rate, or 0.004424 millimeters / minute) according to the ASTM C336 algorithms. Or, if preferred, a separate, independent computer system (not included) can be connected to the Orton controller console via a RS232 port after the test is concluded. The data stored by the Orton on board computer is transferred to the independent computer's hard drive in text file format for later independent review, analysis, or permanent storage.

|

|

|

|

v 建成科學儀器股份有限公司 | 網 址: www.ssco.com.tw | 服務電話: (02) 29103818 | 傳 真: (02) 29101316 v |