The task for rubber manufacturers is to identify rubber additives

that con be used either singly or in conjunction to produce rubber

parts to a high quality and with the high levels of ozone resistance

needed for a long service life. Examples of the types of product for

which this is expected include windscreen wipers, door and window

seals, and, of course, tires. Accelerated static and dynamic tests

can be carried out in a chamber with a controlled ozone dosage that

is monitored to ensure compliance with standard test conditions.

Performances of rubber compounds and additives are assessed through

comparison of both appearance and mechanical properties after

various levels of ozone exposure, for various times, as specified in

testing procedure.

- Basic principles

- Figure 1 shows an example of a chamber for the determination

of a rubber's resistance to ozone cracking under static and

dynamic conditions according to DIN-53509, ISO-1431-1 and

ISO-1432-2.

-

- Components

- Repeatability of ozone cracking results can only be guaranteed

if reliable ozone monitors, ozone generators and well-vented

chambers are available.

- Ozone monitor

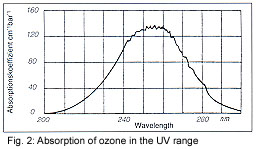

- Anseros has been a leading manufacturer of ozone analysers for

the last 17 years. A non-dispersive ultra-violet monitor (NDUV)

is used for rubber testing that operates using the one-beam

principle. Sensitivity drift cannot occur since automatic zero

adjustment is made by a built-in microprocessor. The absorption

of UV light at a wavelength of 254nm (Fig. 2) is put to

practical use in the NDUV ozone monitor produced by Anseros. The

unit can be made to measure ozone concentration in volume terms

as parts per million (ppm) or parts per hundred million (pphm).

Alternative measurements in terms of mass concentrations of

micrograms per cubic metre (ug/m3) or milligrams per cubic metre

(mg/m3) are also possible, using a conversion based on the

formula:

- Conc. O3(mg/m3) = Conc. O3(pphm) x P/T x 10

-3

- (Where P equals pressure in hectaPascals (hPa) and T equals

temperature in degrees Kelvin).

- Ozone generator

- Ozone can be generated from ambient air using either a UV lamp

(Anseros

Peripheral COM-UV-PID) or via corona

discharge (Anseros Peripheral COM-GD-PID). The

UV lamp principle is simple to use and offers a high level of

stability, however the ability to provide capacity control for a

corona discharge tube is much greater. The volume of ozone that

has to be generated depends on the following:

- Set point of ozone concentration

- Temperature

- Mass of rubber material

- Humidity

- Dust

- Other organic contaminants

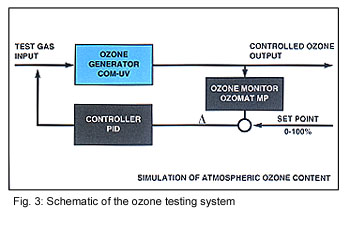

In either case, both methods of extracting the ozone from ambient

air have to be controlled. To achieve this control. Anseros has

developed a special digital PID control with feedback for its ozone

test chambers (Fig. 3).

詳細資料請參閱相關網頁

ANSEROS OZONE PRODUCTS

詳細資料請參閱相關網頁

ANSEROS OZONE PRODUCTS

|

|

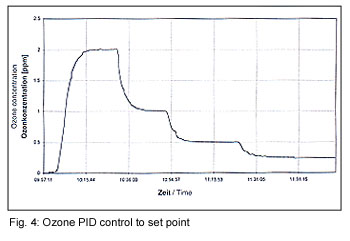

The Anseros PID ozone control unit provides for easy sampling and

monitoring of the ozone concentration in the cabinet. The ozone

concentration is increased on an asymptotic curve to the control

setpoint to prevent the rubber sample being exposed to higher levels

of ozone that would cause premature failure and inconsistent results

(Fig. 4)

- Ozone test chamber

- Anseros only manufactures stainless steel inlets available in

volumes ranging from 35 to 8,000 litres. The air velocity inside

the chamber reaches 600 mm/sec driven by an additional fan. The

operation of the cabinet is according to DIN-53509, with air

inside the chamber being replaced three times per hour (or as

demanded in DIN standards for other volumes of test chamber),

and the required ozone concentration being achieved within 30

minutes from the commencement of the test or change in setpoint

(NB: ASTM requirements slightly differ from this). Generally,

four types of static and dynamic test equipment can be installed

in Anseros ozone chambers:

-

Static test without rotation

-

Dynamic test without rotation

-

Static test with rotation

-

Dynamic test with rotation

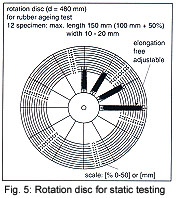

If the test equipment that is necessary to carry out

rotating dynamic tests in installed in the chamber, the chamber has

the capability to carry out the other three forms of test. The

rotation disc procedure guarantees that test conditions to ISO-1431-1

are met for every sample that is tested. Fig. 5 shows a rotation disc

for 12 samples, along with a scale to indicate sample extension. The

rotation frequency is 12 rpm in accordance with ISO 1431-1, but

alternatively can be set to individual customer specifications. A

typical standardised ozone test chamber is shown in Fig. 6. The

chamber of this machine has a capacity of 50 litres, is equipped with

an Ozomat MP6080 ozone monitor, a digital ozone generator, a PID

controller and an ozone concentration, temperature and humidity

recorder. The unit is designed and fitted out for undetectable

mounting.

|