|

|

| SECTION I - PROFILING |

| Mean Velocity (U) Definition |

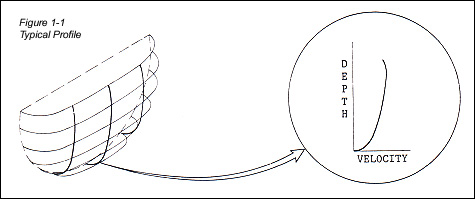

A particle of water near the

conduit wall will not move as fast as a particle toward the center. To understand this, we

need to look at the molecules of moving liquids. The first layer of molecules stick to the

wall of the conduit. The next layer will move by sliding across the first layer. This

happens throughout the flow with each successive layer moving at a faster velocity. The

change in velocity is greater mean the conduit wall than it is toward the center. If

velocity measurements of each layer could be taken, a velocity profile similar to the one

in Figure 1-1 would be produced. Notice that the velocity decreases near the surface

because of surface effects. Since most flows fit this profile, this is called the typical

profile. There are, however, situations which will cause other profile shapes and it is

usually more difficult to calculate flow with these shapes.

|

|

To calculate flow, an average or mean of all the varying

velocities must be determined. Since it is not practical to measure the velocity of each

layer of molecules, methods have been developed with which a mean velocity (U) can be

determined from velocity measurements taken at various positions in the flow. |

|

|

|

| Cross-Sectional Area |

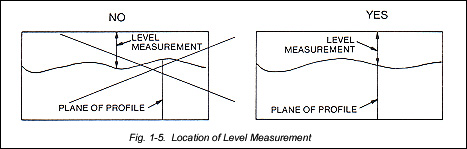

| The cross-sectional area of the

flow is determined from a level measurement and the channel shape. It is important that

the mean velocity measurement and the level measurement is done at the same location in

the channel. |

| Site Selection |

| A site that produces the typical

profile shape will give the most accurate results. In a majority of the cases, problem

sites can be identified by a visual inspection. Site inspection guidelines are as follows: |

- The channel should have as much straight run as possible.

Where the length of straight run is limited, the length upstream from the profile should

be twice the downstream length.

- The channel should be free of flow disturbances. Look for

protruding pipe joints, budden changes in diameter, contributing sidestreams, outgoing

sidestreams, or obstructions. Clean any rock, sediment, or other debris that might be on

the bottom of the pipe.

- The flow should be free of swirls, eddies, vortices, backward

flow, or dead zones. Be careful of areas that have visible swirls on the surface.

- Avoid areas immediately downstream from sharp bends or

obstructions.

- Avoid converging or diverging flow (approach to a flume) and

vertical drops.

- Avoid areas immediately downstream from a sluice gate or

there

the channel empties into a body of stationary water.

|

| Choosing The Method |

| All profiling methods can be used

in a site that produces a typical profile and has sufficient level to measure three point

velocities. If you cannot avoid sites with nontypical profiles or low flows, the following

guidelines will help in choosing a method that will give the best results. |

|

Low Flows - In flows of less than two inches, the 0.9 x Vmax

method is recommended.

Rapidly Changing Flows - A flow that is changing more than

10% in three minutes or less can be classified as rapidly changing. The 0.9 x Vmax or 0.4

methods take the least amount of time. However, these methods usually require a typical

profile shape for accurate results.

Asymmetrical Flow - There will be a difference of 30% or more

between the right and left side velocities in asymmetrical flow. The 2-D method is

recommended.

Vertical Drop (outfalls) - The 2-D method is recommended for

outfalls. Remember to measure the level on the same plane as the velocity profile.

Outfalls should be avoided wherever possible.

Nontypical Profile Shape -- If you suspect a profile shape

may not be typical, use the 2-D method.

Choosing the method will become easier as you gain

experience.

|

Profiling Checks |

For best possible results, you

should:

- Check the inside diameter of the conduit. Also measure the

horizontal and vertical diameters. If there is a difference, then average the diameter.

- Check for symmetry of flow.

- Check level several times furing the procedure.

- Check the invert for rocks, sediment, and other debris.

|

|

|

| Calculating U 0.9 x Vmax Method |

- Take a series of point velocity measurements throughout the

intire flow.

- Identify the fastest velocity. In most cases, this is usually

located in the center just beneath the surface.

- Multiply the fastest velocity by 0.9 for U.

|

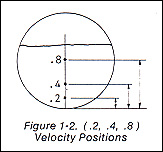

| Calculating U 0.2, 0.4, 0.8 of Depth

Method |

- Measure depth of flow

- Locate possitions on the centerline by: 0.2 x depth., 0.4 x

depth., 0.8 x depth

- At 0.2, 0.4 and 0.8 positions, measure and record the point

velocities (Fig. 1-2). In manmade channels, measure the 0.2, 0.4 and 0.8 positions from

the bottom.

- Average 0.2 and 0.8 velocities.

- Average the 0.4 velocity with the 0.2 and 0.8 average for U

|

|

|

|

|

| Calculating U 0.4 Method |

| A simplified version of the .2,

.4, .8 method is to measure the velocity at the .4 position and use this as U. This method

is probably the least accurate because it uses only one data point and assumes that a

typical profile exists. This is also called the 60% of depth methods. |

|

|

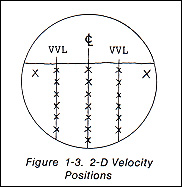

| Calculating U 2-D Method |

- Locate the centerline of the flow.

- Take at least seven velocity measurements at different depths

along the centerline.

- Average all measurements except outliers for U. Remember to

include the corner measurements.

|

- Locate vertical velocity lines

(VVL) halfway between the

centerline and the side smalls of the conduit. This is measured at the widest part of the

flow.

- Take velocity readings at different depths on the VVL. The

distance between those depths should be the same as those on the centerline.

- Take final point velocity readings

at the right and left

corners of the flow.

- Check the data for any outliers. If a best fit curve of the

velocity profile were plotted, an outlier would lie outside the best fit curve region.

|

|

|

| Calculating U VPT Method |

| The Velocity Profiling Technique

(VPT) was first described by N.T. Debevoise and R.B. Fernandez in the November 1984 issure

of the WPCF Journal. With this method, a series of point velocity measurements are taken

at different depths along the centerline of the flow. These measurements along with level

are input not a VPT computer program which calculates U and flow. The program and a

detailed description of this method is available from MMI. |

|

|

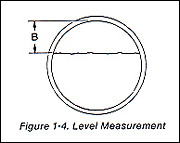

Measuring Level Circular Conduits

- Measure the inside diameter of the conduit.

- Measure distance B (Fig. 1-4)

- Subtract B from the inside diameter of the conduit for the

depth of flow. This eliminates the problem of the rules interfering with the liquid.

|

|

|

|

The level measurement and the velocity profile must be on

the same plane for proper application of the continuity equation.

|

|

|

|

|

| SECTION II - CALCULATING FLOW |

| Circular Conduits |

To calculate flow in circular conduits you need:

- The mean velocity U from Section I

|

|

- The depth of flow at the time of profile.

- The inside diameter of the conduit

|

| Calculate level/diameter ratio by:

L ÷ D = L/D |

|

Where:

L is depth of flow in inches at time of profile

D is the inside diameter in inches.

L/D is level/diameter ratio |

| Where: K is flow unit multiplier. |

|

Find the appropriate L/D ratio in the L/D column and move to

the right to the K in the appropriate units column. |

| Calculate D² by: (Diameter Inches

÷

12)² |

|

Where: D² is diameter in feet squared.

This matches the velocity unit of ft/sec. |

| Calculate flow by: K x D² x U = flow |

|

Example: What is the flow in

millions of gallons per day of a

10-inch diameter conduit with a 6-inch level? The U has been calculated to be 1.5 ft/sec. |

| Calculate level/diameter ratio L/D: |

|

Level ratio L/D = 6 inches/10 inches = 0.6 |

| Identify K: |

|

K = 0.6 --> 0.3180 from Table II |

| Calculate D² |

|

D² = (10 in. ÷ 12

)² = (0.83 ft)² 0.6889 ft² |

| Calculate flow: K x D² x U = MGD |

|

0.3180 x 0.6889 ft² x 1.5 ft / sec =

0.328 MGD |

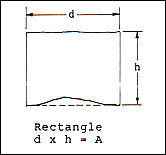

| Calculating Flow Rectangular Channel |

|

|

| Flow in rectangular channels is calculated by the following: |

|

- Determine U with the .2, .4, .8 method as described on above.

For large channel widths, use the .2, .6, .8 method as described on above for rivers and

streams. Velocity units must be in ft/sec.

- Calculate the cross-sectional area in ft²

by: [(Depth of Flow) in. ÷ 12] x [(Channel Width) in. ÷

12]

- Calculate flow by: U x (Cross-sectional area)

|

The result should be a flow rate in ft³

/sec. You can convert this to other flow units with the flow unit conversion multipliers

in attach. table. Example: What is the flow in a channel 24 inches wide with a 10-inch

flow?

| Solution: |

|

- Velocity measured at .2 = 1.5 ft / sec.

- U = (1.5 + 1.7 + 1.8) ÷ 3 = 1.67 ft/sec.

- From table 1 10 in. = 0.83 ft.

- Area = 0.83 ft x 2 ft = 1.66 ft²

- Flow = 1.67 ft² / sec. x 1.66 ft = 2.77 ft³

/ sec.

|

Calculating Flow Rivers and Streams

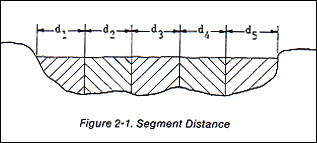

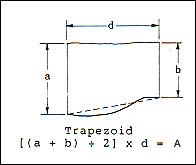

| Divide the width of the channel into a number of equal

segments with a distance "d" (Fig. 2-1). The more segments you use the better

the result. If the difference in mean velocity between two adjacent segments is greater

than 10%, the segments should be smaller. |

|

|

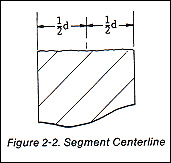

- Locate the center line for each segment at 1/2 d (Fig. 2-2)

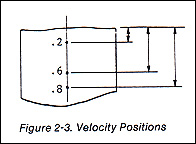

- Calculate .2, .6, .8 velocity position by:

- 0.2 x Depth.,

- 0.6 x Depth.,

- 0.8 x Depth.

- Measure the velocity at the 0.2, 0.6, and 0.8 positions.

|

|

|

| (NOTE) The 0.2,

0.6, and 0.8 positions for rivers and streams are measured from the surface. All depth and

velocity measurements must be on the same plane.

|

|

|

- Average the 0.2 and 0.8 velocities.

- Average the 0.6 velocity with the average of the 0.2 and 0.8

velocities for U.

- Calculate the flow of each segment by: (Segment Area) x U

- Sum the flow of the segments for total flow.

|

|

|

|

| Example: |

|

Convert 20 ft³ /sec (CFS) to millions of

gallons per day (MGD). |

| Solution: |

|

- Conversion factor = 0.64632.,

- 20 ft³ /sec x 0.64632 = 12.9264 MGD

|

Flow Units

| MGD -- Millions of Gallons per Day |

|

CMM -- Cubic Meters per Minute |

| GPM -- Gallons per Minute |

|

CMD -- Cubic Meters per Day |

| CFS -- Cubic Feet per Second |

|

LPM -- Liters per Minute |

|

|

|