Nabertherm is renowned

as one of the leading companies in the branch for almost 50

years.

GERO is established

in the market as a manufacturer of technologically sophisticated

furnaces with application temperatures of up to 3,000°C.

The sintering process is a major step in the production of

technical ceramics. Controlled atmospheres and temperatures are

necessary to create homogeneous textures. Tailor made furnace

design is essential to manufacture high quality ceramic

components.

Nabertherm and GERO

offer a range of high temperature furnaces with the following

features:

- chamber, hood, shaft and tube furnaces

- temperature range from 300 to 3000°C

- volumes from 1 to 20,000 litres

- gas sweeping (nitrogen, oxygen, argon and hydrogen)

- vacuum systems for as low as 10³ bar

- special furnace insulation for aggressive media

- catalyst to decontaminate exhaust gases

- switchgear from program control to all automatic operation

control

- multizone control for temperature gradients of ±1K

The following gives a selection of Nabertherm

and GERO sintering

furnaces:

1. Chamber Furnace HT 160/16/S3

The chamber furnace HT160/16/S3 (Fig. 1) is designed to

manufacture ceramic components at 1,600°C. Gas sweeping allows

sintering in controlled atmospheres. A magnetic door lock

prevents the furnace from opening while in operation. 2 program

controllers operate redundantly. i.e. in case of failure of the

main controller, the sintering process is automatically

continued by the safety controller.

Fig. 1: Chamber Furnace HT160/16/S3

(Nabertherm)

2. Hood Furnace HT64/17/LTS

The HT64/17/LTS (Fig. 2) is used for sintering oxide ceramics

at a temperature of 1,750°C. Four-sided heating guarantees

extremely good temperature distribution. Fast heating and

cooling and low heat loss is provided by insulation made of

high-quality vacuum thermoformed Al2O3-fibre plates. A thyristor-controlled

switchgear guarantees a consistent temperature accuracy of ±2K.

Fig. 2: Hood Furnace, HT 64/17/LTS (Nabertherm)

3. Chamber Furnace HTZ 01/20

Nabertherm is able to offer a chamber furnace for a maximum

temperature of 2,000°C in oxidising atmospheres (Fig. 3). The

outer chamber is heated by 4 Kanthal-Super elements. The inner

chamber with a volume of 1 litre is zirconia insulated and

heated by 4 zirconia elements. Both chambers are controlled

separately and follow fixed heating and cooling rates.

Fig. 3: Chamber Furnace HTZ01/20 (Nabertherm)

4. Chamber Furnace HT 276/17

The chamber furnace HT276/17 (Fig. 4) is designed to sinter

oxide ceramics at 1,700°C. The furnace is equipped with a

warm-air inlet (fan and heater) to guarantee excellent

temperature distribution and to transport the outgoing binder to

the catalyst. The furnace has doors on both sides for easy and

comfortable loading.

Fig. 4: Chamber Furnace HT 276/17 (Nabertherm)

5. Hood Furnace HT 180/17/LTS

The furnace is equipped with a moveable hood and two

electrically moveable tables (Fig. 5). In a useful volume of 180

litres, oxide ceramics are sintered at a temperature of 1,700°C.

Continuous charging and utilisation of stored heat result in

economical and efficient production cycles. The switchgear is

equipped with a control system to control all electrical

movements. Four-sided heating by 23 Kanthal-Super elements

provides excellent temperature distribution. To increase the

cooling rate, the hood is lifted gradually from 1,100°C on.

Fig. 5: Hood Furnace HT180/17/LTS (Nabertherm)

6. Shuttle Kiln W1260/14/S

The shuttle kiln W1260/14/S (Fig. 6) was designed with the

requirement that the charge of thin-walled ceramic tubes should

be free from shock or vibration. Therefore, the furnace was

designed for moving on rails while the table remains fixed.

Production takes place in three similar furnaces of 1260 litres

at 1,340°C. Five-sided heating and four-zone regulation

guarantee excellent temperature distribution.

Fig. 6 Shuttle Kiln W1260/14/S (Nabertherm)

|

|

7. Shuttle Kiln W10800/HS1

Ceramic grinding wheels are manufactured at Slip Naxos of

Vastervik/Sweden at a temperature of 1,340°C. The production

takes place in six shuttle kilns W10800/HS1 (Fig. 7).

Five-zone-regulation provides extremely good temperature

distribution in a useful volume of 10,800 litres. A programmable

cooling fan in combination with automatically driven vapour vent

flaps results in short cooling terms.

Fig. 7 Shuttle Kiln W10800/HS1 (nabertherm)

8. Hood Furnace HT1010/17/LTS

The HT1010/17/LTS (Fig. 8) is designed to manufacture thin

walled tubes made of oxide ceramics. At a temperature of 600°C

the binder is burned-out and subjected to catalytic afterburing.

The sintering process takes place at a temperature of 1,700°C.

30 Kanthal-Super elements guarantee temperature distribution of

±5K in a volume of 1010 litres. Due to a specially constructed

base, the furnace can be charged with a load of as much as 1200

kg/m².

Fig. 8 Hood Furnace

HT1010/17/LTS (Nabertherm)

9. Hood Furnaces N352/AS and HT352/17/LT

The forced-air oven N352/AS and the high temperature furnace

HT352/17/LT (Fig. 9) are designed to burn-out the binder of

oxide ceramics at 600°C and sinter the material at 1,700°C

without unloading the bogie. Four-sided heating guarantees

temperature distribution of ±5 K in a useful volume of 352

litres.

10. Hood Furnace HBO/400

The HBO/400 (Fig. 10) can be operated under vacuum or

non-oxidising

atmospheres at a maximum temperature of 2,000°C. Insulation and

heating elements are made of graphite. Charging occurs from

above when the hood is raised. Dornier at Immenstaad/Germany

uses the HBO/400 for manufacturing fibre reinforced ceramics.

The chamber is evacuated and swept with nitrogen twice in order

to obtain an inert atmosphere. Temperatures. evacuation, gas

sweeping and hood movements are controlled automatically.

Fig. 10: Hood Furnace HBO/400 (GERO)

11. Ten Zone Tube Furnace ZZ200-2000

The ZZ200-2000 (Fig. 11) is designed for heat treatment of

ceramic superconductor materials. During 3 heating periods of 40

h each, 2000 mm long wires are tempered at 830°C. Due to a ten

zone regulation, temperature distribution of ±0.5 K can be

attained.

Fig. 11: Ten Zone Tube Furnace ZZ200-2000

(GERO)

12. Tube Furnace BKZ 20-500/5

Hoechst AG at Frankfurt/Main, Germany uses the BKZ 20-500/5

(Fig. 12) to produce ceramic superconductor materials at a

maximum temperature of 1,500°C. The zone melting process

requires extreme temperature gradients to ensure that only a

small area of the speciment is liquefied. This offers the chance

to grow monocrystals without changing the specimen's shape. The

plant is fibre insulated and heated by Pt-Rh heating elements.

The vertical five-zone tube furnace moves at 1 mm/h over the

bar-shaped specimen (10 mm in diameter). The middle heating zone

provides a power of 120 W over 20 mm length which leads to a

temperature gradient of 140 K/cm.

Fig. 12: Tube Furnace BKZ 20-500/5 (GERO)

13. Hood Furnace HBO 250

The HBO 250 (Fig. 13) is used for tempering ceramic

superconductors for 40 h at 800°C in a pure oxygen atmosphere.

With assistance of a centric heating section, a temperature

gradient of ±1 K is not exceeded even during heating and

cooling periods. Due to a mobile, high temperature cone made of

heat resisting steel, a cooling time of 4 h can be reached.

Fig. 13: Hood Furnace HBO 250 (GERO)

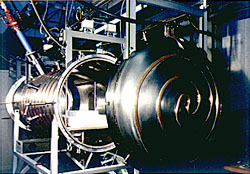

14. Microwave Sintering Plant

Using microwave for sintering ceramic components is still

new: The direct application of energy into the material allows

fast and homogeneous heating. Microwave sintering causes smaller

grains, bitter material properties and lower sintering

temperatures.

GERO is developing, in cooperation with the Institute for

Plasma Research (IPF). Stuttgart, a production plant of 500

litres volume for sintering silicon nitride and alumina

components. A plant of 40 liter is already in operation at a

working frequency of 28 GHz (Fig 14), The production plant will

allow a process temperature of up to 1,700°C and can operate at

2.45 or 28 GHz.

Fig. 14: Microwave Sintering Plant

|