Place

an extruded column of a green ceramic, a row of pressed discs or parts,

a trough of granular raw material, or a glazed substrate on the D-tube

hearth and into the Orton MD Series Gradient Furnace. Set the controller

for a specific thermal cycle, them walk away to perform other tasks.

After the furnace cools, remove the samples and record their position on

the D-tube hearth. Since one end of the row of materials was cooler then

the other, you can immediately see how the range of firing temperatures

affected the shrinkage, color, porosity, particle size, degree of

vitrification, and other ceramic properties that are temperature

dependent. Place

an extruded column of a green ceramic, a row of pressed discs or parts,

a trough of granular raw material, or a glazed substrate on the D-tube

hearth and into the Orton MD Series Gradient Furnace. Set the controller

for a specific thermal cycle, them walk away to perform other tasks.

After the furnace cools, remove the samples and record their position on

the D-tube hearth. Since one end of the row of materials was cooler then

the other, you can immediately see how the range of firing temperatures

affected the shrinkage, color, porosity, particle size, degree of

vitrification, and other ceramic properties that are temperature

dependent.

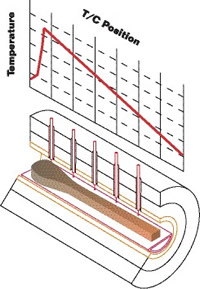

The Orton Model GTF-MD-15

(1,500°C maximum) and GTF-MD-16 (1,600°C maximum) Series Furnaces are

a specially designed horizontal tube furnaces with controlled,

reproducible, linear thermal gradients of approximately 120°C across a

12" long monitored zone. The Orton Model GTF-MD-15L and GTF-16L

Series Furnaces are longer versions with controlled, reproducible,

linear thermal gradients of approximately 320°C across a 16" long

monitored zone. Thermocouples on 2" centers monitor the

temperatures along the gradient zone, so the temperature of the material

at any position along the D-tube hearth is known. Visual or post firing

analyses of sections taken from the fired material at any position along

the D-tube hearth can be measured, recorded, and studied as a function

of temperature.

|

The Orton GTF-MD Series

Furnace is a specially designed horizontal tube furnace with a

controlled, reproducible, approximately linear thermal gradient across a

12" or 16" long monitored zone. |

|

The furnace is a

rectangular, metal shell structure that houses the

refractory fiber insulation and four molybdenum disilicide heating

elements that surround one end of the 3” ID ceramic heating

chamber tube. The samples to be fired are placed on the top of the

2.5” wide high alumina D-tube hearth, which rests on the bottom of

the ceramic heating chamber tube. Type “S” thermocouples are

spaced on 2” centers along the monitored zone and extend

vertically through the top of the heating chamber tube. Two

specially shaped IFB end plugs are included to cover both ends of

the furnace.

|

|

The furnace temperature is

controlled by the Universal Temperature Control Console (UTC). The

UTC contains the user programmable, multi-segment PID controller,

the phase-angle-fired SCR solid state power module, ammeter, ON/OFF

power switch and appropriate electrical receptacles. The PID

controller uses the thermocouple at the hot end of the furnace for

control, so the monitored gradient falls from this control

temperature.

|

|

Electrical power from the

UTC runs through the included step-down transformer and on to the

molybdenum disilicide heating elements.

|

|

The Temperature Display

Cabinet contains a digital panel display, rotary selector switch and

appropriate electrical receptacles to display the temperatures of

the other thermocouples along the length of the monitored zone. The

system includes all interconnecting cables and instruction manual.

The Temperature Display Cabinet requires 120 VAC, 15-amp power. The

UTC requires 240 VAC, 20-amp, 50/60 hertz input power. |

|

|

|

|

Place

an extruded column of a green ceramic, a row of pressed discs or parts,

a trough of granular raw material, or a glazed substrate on the D-tube

hearth and into the Orton MD Series Gradient Furnace. Set the controller

for a specific thermal cycle, them walk away to perform other tasks.

After the furnace cools, remove the samples and record their position on

the D-tube hearth. Since one end of the row of materials was cooler then

the other, you can immediately see how the range of firing temperatures

affected the shrinkage, color, porosity, particle size, degree of

vitrification, and other ceramic properties that are temperature

dependent.

Place

an extruded column of a green ceramic, a row of pressed discs or parts,

a trough of granular raw material, or a glazed substrate on the D-tube

hearth and into the Orton MD Series Gradient Furnace. Set the controller

for a specific thermal cycle, them walk away to perform other tasks.

After the furnace cools, remove the samples and record their position on

the D-tube hearth. Since one end of the row of materials was cooler then

the other, you can immediately see how the range of firing temperatures

affected the shrinkage, color, porosity, particle size, degree of

vitrification, and other ceramic properties that are temperature

dependent.